SERVICES

Supplying Complete System For Any Oil Cleaning Services

Supplying Complete System For Any Oil Cleaning Services

Centrifugal Oil Cleaner (Motor)

Improve Product Quality, Reduce Oil Expenses

• No Filter Element

• No Replacement Cost

• Improved Product Finish

• Reduced Oil Consumption

• Extended Oil Change Period

• Reduced Machine Downtime

• Reduced Pollution & Environment Impact

• Reduced Storage & Disposal Cost of Waste Oil

Substantial Savings on Cost of Filters, Tools / Dies & Oil replacement

Application:

• Soluble Cutting Oil

• Neat Cutting Oil

• Water Emulsion

• Nut/Bolt Forming

• Thread Rolling

• Honing / Grinding

• Bright Bar Mfg

• Wire Drawing

• Tube Drawing

Save by Extending Oil Life, Tool Life and Machine Life

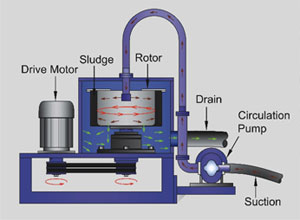

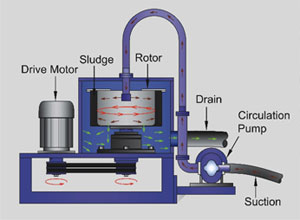

Centrifugal Cleaner removes very fine dirt from Coolant/Lubricant upto 1µ & below by Centrifugal force created in centrifuge rotor. Conventional filters can not remove such fine dirt. There are no consumable hence no recurring cost. Collected dirt can be easily cleaned & the unit put back to use again.Working Principle

The Lubricant to be cleaned is passed through a rotor, driven by Electric Motor. Centrifugal force 2000 times gravity is exterted on the particles, depositing them on inner wall of rotor as dense cake. Clean oil returns back to the tank. Collected sludge can be easily cleaned and unit put back to use again. With clean oil, wear of tools and dies is reduced and job finish is improved. the oil need not be replaced frequently, thereby saving substantially on oil expenses and protecting Environment.Installations

The Lubricant to be cleaned is passed through a rotor, driven by Electric Motor. Centrifugal force 2000 times gravity is exterted on the particles, depositing them on inner wall of rotor as dense cake. Clean oil returns back to the tank. Collected sludge can be easily cleaned and unit put back to use again. With clean oil, wear of tools and dies is reduced and job finish is improved. the oil need not be replaced frequently, thereby saving substantially on oil expenses and protecting Environment.Installations

Centrifugal Cleaner removes very fine dirt from Coolant/Lubricant upto 1µ & below by Centrifugal force created in centrifuge rotor. Conventional filters can not remove such fine dirt. There are no consumable hence no recurring cost. Collected dirt can be easily cleaned & the unit put back to use again.Working Principle

The Lubricant to be cleaned is passed through a rotor, driven by Electric Motor. Centrifugal force 2000 times gravity is exterted on the particles, depositing them on inner wall of rotor as dense cake. Clean oil returns back to the tank. Collected sludge can be easily cleaned and unit put back to use again. With clean oil, wear of tools and dies is reduced and job finish is improved. the oil need not be replaced frequently, thereby saving substantially on oil expenses and protecting Environment.Installations

The Lubricant to be cleaned is passed through a rotor, driven by Electric Motor. Centrifugal force 2000 times gravity is exterted on the particles, depositing them on inner wall of rotor as dense cake. Clean oil returns back to the tank. Collected sludge can be easily cleaned and unit put back to use again. With clean oil, wear of tools and dies is reduced and job finish is improved. the oil need not be replaced frequently, thereby saving substantially on oil expenses and protecting Environment.Installations

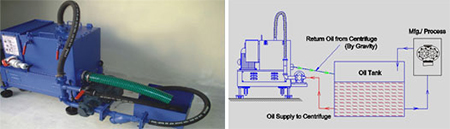

Schematic Diagram